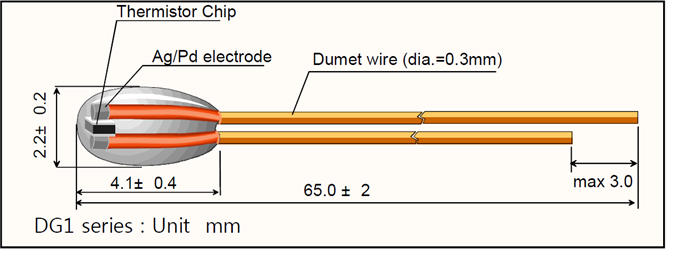

Glass size : Ø 2.2mm standard size

Operating up to 300°C with high stability

Excellent stability at high humidity condition (tight glass sealing)

Cost effective design

Certified UL DG series (File No. E340044)

Glass sealing type thermistor is designed for high environmental reliability and wide temperature range of usage (-50°C ~ 300°C)

Glass size : Ø 2.2mm standard size

Operating up to 300°C with high stability

Excellent stability at high humidity condition (tight glass sealing)

Cost effective design

Certified UL DG series (File No. E340044)

Operating temperature | -50 ~ 300°C |

Thermal time constant | Max. 11sec(in still air) |

Resistance tolerances | ±0.5%, ±1.0%, ±2.0%, ±3.0%, Special |

Dissipation constant | 1.0 ~ 1.5mW/°C |

Insulation resistance | 500VDC Min 50Mohm (Between lead and glass) |

> Explanation of Part No.

DG1 | B | 103 | F | B | - | X |

Type | RT Curve | Resistance | Tolerance | Reference temp.(°C) | Packing type | |

Glass size of | R-T curve | 502=50X100 | F : R±1%, B±1% | A :0°C Other ... | Blank : Bulk A : Ammo taping B : Reel taping |

> Part No List.

Part No. | Resistance temperature

| Resistance

| B value | ||||||

DG&A502xB | 25 | 5 | B25/85 | 3970, 3977 | |||||

DG&A103xB | 25 | 10 | |||||||

DG&A203xB | 25 | 20 | |||||||

DG&B103xB | 25 | 10 | B25/85 | 3435 | |||||

DG&B27.62xA | 0 | 27.62 | |||||||

DG&C49.12xB | 25 | 49.12 | B25/85 | 3990 | |||||

DG&C503xB | 25 | 50 | B25/85 | 3990 | |||||

DG&C29.46x37 | 37 | 29.46 | |||||||

DG&C17.59xC | 50 | 17.59 | B0/100 | 3970 | |||||

DG&C8.514xD | 70 | 8.514 | |||||||

DG&C332xF | 100 | 3.3 | |||||||

DG&C133.5xJ | 4 | 133.5 | |||||||

DG&C135.5xJ | 4 | 135.5 | |||||||

DG&D104xB | 25 | 100 | B25/85 | 4060 | |||||

DG&D14.20xS | 75 | 14.20 | B0/100 | 4000 | |||||

DG&D6.282xF | 100 | 6.282 | |||||||

DG&D551xH | 200 | 0.550 | B100/200 | 4330 | |||||

DG&D983xB | 25 | 98.64 | B25/85 | 4066 | |||||

DG&E234xB | 25 | 230 | B25/85 | 4250 | |||||

DG&E104xB | 25 | 100 | |||||||

DG&E103.9xB | 25 | 103.9 | |||||||

DG&E133xF | 100 | 13.09 | B100/200 | 4537 | |||||

DG&E15.78xK | 95 | 15.78 | |||||||

DG&E3.241xG | 150 | 3.241 | |||||||

DG&E102xH | 200 | 1 | B100/200 | 4550 | |||||

DG&E1.175xH | 200 | 1.175 | B100/200 | 4550 | |||||

DG&E3.4513x114 | 114 | 3.4513 | B25/50 | 4200 | |||||

DG&F502xB | 25 | 5 | B25/85 | 3324 | |||||

DG&F13.29xA | 0 | 13.29 | B0/25 | 3200 | |||||

DG&G6.000xA | 0 | 6 | B0/100 | 3390 | |||||

DG&G2.186xB | 25 | 2.186 | B25/85 | 3420 | |||||

DG&J10.74xB | 25 | 10.74 | B0/100 | 3450 | |||||

DG&J3.485xC | 50 | 3.485 | |||||||

DG&J1.325xJ | 90 | 1.325 | |||||||

DG&M104xB | 25 | 100 | B25/85 | 3990 | |||||

DG&N135xB | 25 | 1.388 | B25/85 | 4550 | |||||

DG&N135xB | 25 | 1.300 | |||||||

DG&M10.65xE | 85 | 10.65 | B25/50 | 3950 | |||||

DG&M6.71xF | 100 | 6.71 | |||||||

DG&F5.369xB | 25 | 5.369 | B25/85 | 3480 | |||||

B0/100 | 3450 | ||||||||

DG&P153xA | 0 | 15 | B0/100 | 3450 | |||||

DG&J202xB | 25 | 2 | B25/50 | 3530 | |||||

DG&J103xB | 25 | 10 | B25/85 | 3520 | |||||

DG&B157xX | 180 | 0.1568 | B25/85 | 3435 | |||||

DG&B176xX | 180 | 0.176 | |||||||

DG&H104xB | 25 | 100 | B25/85 | 4390 | |||||

DG&H1.196xG | 150 | 1.196 | |||||||

DG&A272xB | 25 | 2.7 | B0/50 | 3880 | |||||

DG&K203xB | 25 | 20 | B25/85 | 3690 | |||||

※ Where x – Maybe follow up by S, F, A, G, B, H, C, I or J for resistance tolerance, refer to NOMENCLATURE for detailed.

※ Where y – maybe follow up by W or C for Type, refer to NOMENCLATURE for detailed.

※ The information here can be downloaded from "SUPPORT"

- High temperature sensing, control and compensation

- Automotive for temperature monitoring, controlling & Management

- HVAC & White goods applications

- Industrial Instrumentation

- Medical & Chemical Industry

※ ISTEC specializes in customized products. Please contect us for various options.